Introduction to Photolithography - WC, BLF, PA, Hard and Soft baking

By: HWC

Date Uploaded: 05/12/2020

Tags: homeworkclinic.com Homework Clinic HWC Introduction to Photolithography Wafer Cleaning Barrier Layer Formation Photoresist Application Soft Baking Photoresist Exposure Photoresist Development Hard Baking Silicon Dioxide Etching Photoresist Removal Doping By Ion Implantation silicon wafer silicon dioxide photoresist photomask high intensity ultraviolet light ultraviolet light buffered oxide etch BOE or BHF) hydrofluoric acid p type wafer

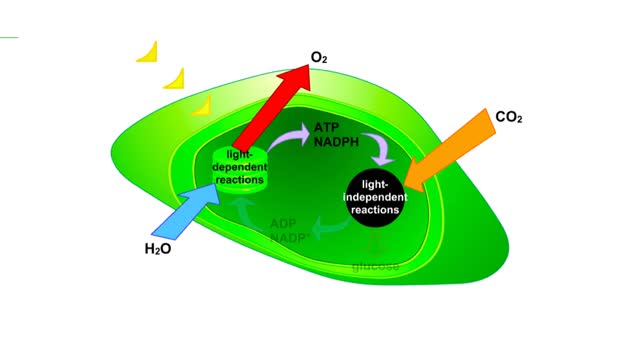

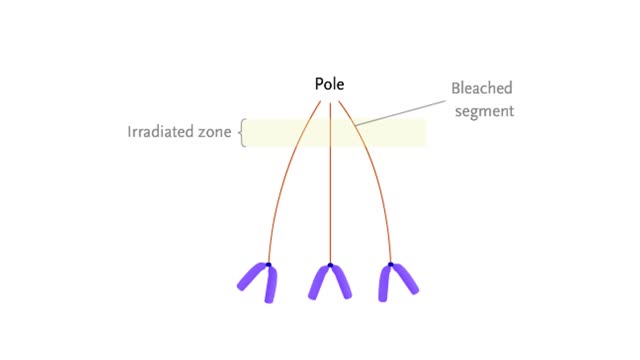

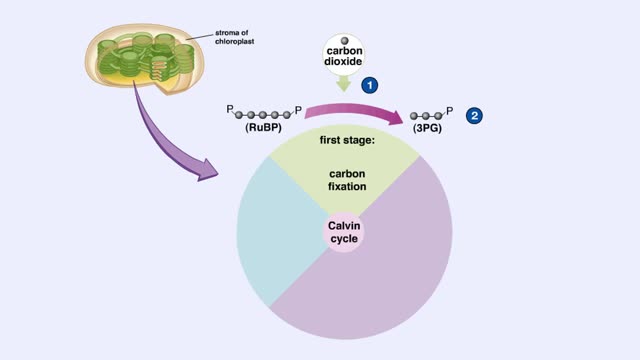

Prior to use, wafers are chemically cleaned to remove particulate matter on the surface as well as any traces of organic, ionic, and metallic impurities. Barrier Layer Formation After cleaning, the silicon wafer is covered with the material which will serve as a barrier layer. The most common material is silicon dioxide (Si02), so we will use it as an example here. The silicon dioxide layer can be grown by putting the silicon wafer in a furnace and heating it to a high temperature in an atmosphere containing either pure oxygen or water vapour. Photoresist Application After formation of the Silicon dioxide layer, the surface of the wafer is coated with a light-sensitive material called photoresist. Photoresist is typically applied in liquid form. The wafer is held on a vacuum chuck and then spun at high speed to produce a thin uniform layer. Soft Baking A drying step called soft baking or prebaking is used to improve adhesion and remove solvent from the photoresist The photoresist-coated wafer is baked in an oven at about 90 degree Celcius for 10 to 30 minutes. Photoresist Exposure A photomask, a square glass plate with a patterned emulsion or metal film on one side, is placed over the wafer. The photoresist is exposed through the mask with high-intensity ultraviolet light Resist is exposed wherever silicon dioxide is to be removed. Photoresist Development The photoresist is developed with a process very similar to that used for developing ordinary photographic film. Any resist which has been exposed to ultraviolet light is washed away; leaving bare silicon dioxide in the exposed areas. Hard Baking Following exposure and development. baking step is used to harden the photoresist and improve adhesion to the substrate A typical process involves baking in an oven for 20 to 30 minutes at 120 degree Celsius. Silicon Dioxide Etching A buffered oxide etch (BOE or BHF)is commonly used to etch windows in silicon dioxide layers. BOE is a solution containing hydrofluoric acid (HF), and etching is performed by immersing the wafers in the solution. At room temperature, HF etches silicon dioxide much more rapidly than it etches photoresist or silicon. Photoresist Removal After windows are etched through the Silicon dioxide layer, the photoresist is stripped from the surface, leaving a window in the silicon dioxide Photoresist removal typically uses proprietary-liquid resist strippers. Doping By Ion Implantation The silicon wafer exposed by the silicon dioxide window can then be doped to modify its. This can be done, for example, by implantation of a dopant such as antimony, to form an n-type region in the p-type wafer.

Add To

You must login to add videos to your playlists.

Advertisement

Comments

0 Comments total

Sign In to post comments.

No comments have been posted for this video yet.